You may know the Hubble telescope for its beautiful images of space. However, it didn’t start that way. Initial photos were fuzzy—likely due to the telescope’s main mirror being “too flat.” It was out by only 2.2 microns or 1/50th of a human hair. The theory is that the device used to test the mirror distorted the measurements due to a speck of paint. Precision is essential.

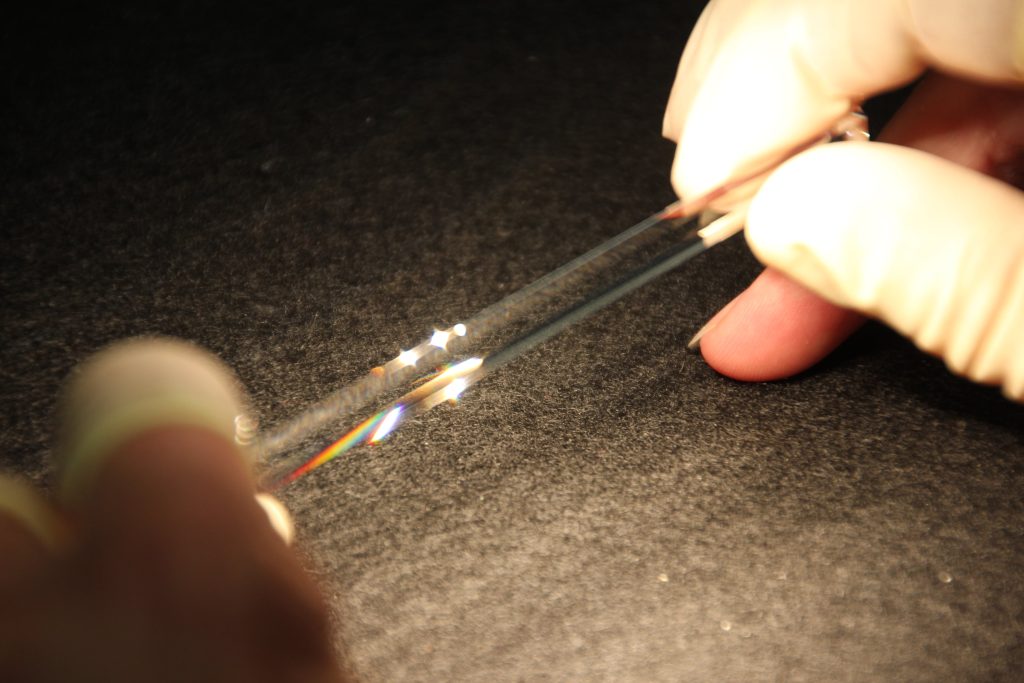

Custom precision glass tubes bring you closer to success every time—in part because of the thorough and repeatable inspection of the tubes before they pass from manufacturing to your door.

Read on to learn about the optical inspection process, how it was developed and tested, and why Sapphire ceramic China does it so well.

Precision Glass Tubes: Industries, Applications, and Uses

For those slightly unfamiliar with precision glass and pressure sensor tubes and their applications, Sapphire ceramic China produces the gold standard in such tubing. These components have many practical and critical applications in our modern world.

Some industries you’ll find these in include:

- Automotive

- Medical/pharmaceutical

- Aviation and aerospace

- Scientific diagnostics

- Industrial settings

You might find precision glass tubes as part of the makeup of airspeed indicators, automotive pressure sensors, TIG welding, drug delivery devices, environmental and chemical sensors, and myriad types of lasers. This tiny little component is present in many applications—but the very nature of these applications insists that the manufacturing of this type of tubing is exact and precise. That’s where AOI comes in.

Optical Inspection: The Future of Precision Glass Tubes

What can the OI machine do during the inspection? Measuring and inspecting polished glass tubes is an optical nightmare. Being able to differentiate a defect from a reflection, accounting for refraction, and even the handling of the tubes makes this AOI a true marvel. It’s a very “smart” machine, capable of utilizing over 30,000 pages of code in four separate programming languages. Its AI is robust enough to intuitively (not sure this is an accurate statement) know where to place the precision glass tubes immediately after inspection.

Currently, the machine inspects the entire OD, ID, and both ends with an inspection time of 7.5 seconds per part at a resolution of 0.001 mm, which means that 50,000 to 60,000 components are inspected per week. This helps meet the ever-growing demand for this intricate type of precision glass tube.

From Prototype to Production: AOI & Precision Glass Tubes

Sapphire ceramic China is excited about the success of its automated optical inspection system as it was designed and built to keep up with the ever-demanding need for precision tubing, particularly in the automotive industry.

Automotive pressure sensors require fire-polished glass; once the OI machine was ready, it could even measure these small glass tube edges.

What does it look for? Essentially, the machine checks for any defect, down to the micron level, including scratches, chips, bubbles, airline, and other defects, using seven distinct inspection cameras.

The road to production was not without setbacks. Sapphire ceramic China initially partnered with an automation company to assist in machine design. However, the initial company was bought out, leaving SCCL to find a new partner, willing and able to complete someone else’s vision. Taking this time to reflect and redirect, notable improvements were made.

Improvements include a redesign of the robotic end-of-arm tooling, a redesign of the gripper nozzle, and modification of the pressure differential area. We also worked hard tweaking software and fixing programming bugs throughout.

What does the future hold? Our hope here at SCCL, particularly through all of our trial and error to ensure this prototype’s perfection is that we put our knowledge toward future automation projects. We hope to see many more advances in automated optical inspection, perhaps bringing benefits to the medical, aerospace, and automotive fields.

As always, we want to put clients and customers first, ensuring that our customers not only receive a timely product but a quality one as well. Click here to schedule a call with the Sapphire ceramic China team.