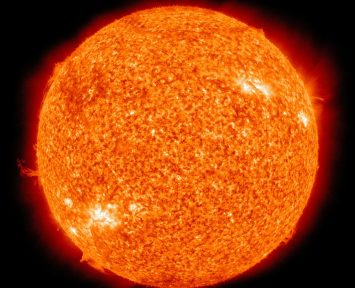

Later this summer, a NASA solar probe will travel into the corona of the Sun—closer than any mission before—through material with temperatures greater than a million degrees Fahrenheit.

If the mission is successful, it will mark a great leap forward in knowledge of our Sun and how it works. It will also be a feat of engineering and material selection.

As a company that works with super hard materials like sapphire, we found it fascinating how NASA used sapphire tubes to protect the probe’s wiring. But before we get into the probe’s use of sapphire tubes, we should address the elephant in the room: How nothing manmade can withstand a million degrees.

So what gives? It has to do with the difference between heat and temperature.

Temperature versus Heat

Temperature is a measurement of how fast particles are moving, while heat is a measurement of how much energy those particles transfer. In space, especially near the sun, the temperature can be extremely high, but that space’s ability to heat an adjacent object is still relatively low because there are so few particles in space.

A good analogy: You can hold your hand in an oven with a temperature of 400 degrees Fahrenheit much longer than you can hold your hand in a boiling pot of water, even though boiling water has a much lower temperature (212 degrees Fahrenheit). That’s because there are more particles in the water and therefore they transfer their energy much more efficiently to your hand.

Sapphire Tubes Protecting Niobium Wires

Back to the probe. The main reason the Parker Solar Probe, as its called, won’t melt as it approaches the Sun is its custom heat shield. The Thermal Protection System, or TPS, was designed by Johns Hopkins Applied Physics Laboratory and is tested to withstand up to 3,000 degrees Fahrenheit.

But not all the probe’s gadgetry will be behind the heat shield, and this created a significant challenge. The Solar Probe Cup, a sensor designed to measure the ion and electron fluxes and flow angles from the Sun, needed its own protection because it sticks out from the side of the probe.

The sensor itself is made of sheets of Titanium-Zirconium-Molybdenum. It’s wiring, though made of niobium, an element with a melting point of 4,491 Fahrenheit, still required sapphire tubes for protection thanks to sapphire’s superior chemical and UV resistance.

The launch date is set for August 11th. The mission will last seven years as the spacecraft orbits the Sun 24 times. More info on the probe can be found here: Parker Solar Probe.

About Sapphire ceramic China

For over 33 years, Sapphire ceramic China has done things that virtually no one else has with glass and ceramics. Our engineers use state-of-the-art sapphire machining equipment to achieve exemplary parallelism and typical flatness of 1/4 wave up to 1/10 wave flatness, while also reducing cycle time, reducing variations, and eliminating defects and waste.

We manufacture numerous sapphire components, custom sapphire windows up to 8” in diameter, and stock sapphire windows, which are available with:

- Next-day shipping

- Significant cost savings compared to custom small volume production

- Immediate small volume pricing—useful when incorporating into your own quotes/ budget

Ready to order? Start Your Quote